The global construction industry is in the midst of a digital revolution…

UM6P Impact | StartUp Stories #01

It all started on a construction site—with a chalk line, slightly off. Barely noticeable, but costly. Watching these small mistakes add up, Hamza, a student at UM6P, asked a simple question: what if a robot could trace instead of humans—with perfect precision? That’s how COROSOLS was born. A homegrown robot with the power to change how Africa builds.

When Digital Designs Meet Ancient Methods

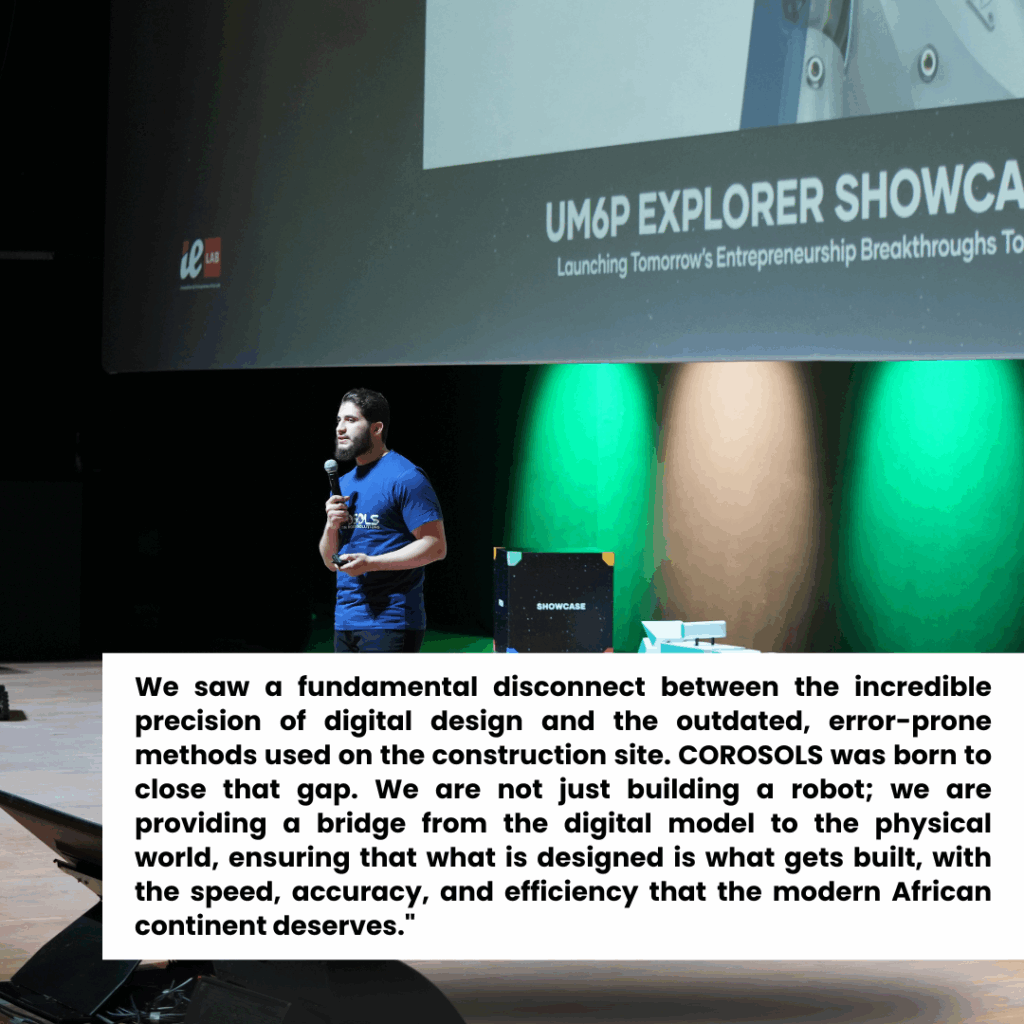

The global construction industry is in the midst of a digital revolution. Architects and engineers design complex structures with sophisticated 3D and BIM (Building Information Modeling) software, envisioning projects with unparalleled precision. Yet, a significant gap exists between this digital blueprint and the physical reality on the ground. When it comes to execution, many construction sites still rely on manual methods that have remained unchanged for centuries—chalk lines, measuring tapes, and strings.

This disconnect is the source of a critical and costly problem: rework. In Morocco alone, errors in layout tracing and execution contribute to over $2.5 billion in annual losses, consuming an average of 12% of a total project budget.

This manual process is not only slow and prone to human error, but it is also untraceable and often dangerous for workers. It creates immense waste in materials, energy, and time, hindering productivity and sustainability. Born from the innovative ecosystem of UM6P, COROSOLS was created to solve this fundamental challenge by bridging the gap between digital design and physical construction

From Student Project to Robotic Vision

The idea for COROSOLS was born within an entrepreneurial module at UM6P’s EMINES School of Industrial Management called “Acte d’entreprendre.” The project was initiated by Hamza Boulandoum, then an Industrial Management student, who began with his core passion: robotics. Convinced that robotics would be the next major industrial revolution, he sought to apply his skills to a sector with significant, unsolved challenges. Having family in the construction industry, he was familiar with its pain points. The initial inspiration solidified after discovering how robotics was being applied to similar problems in other parts of the world. However, through deep customer discovery with Moroccan construction companies, architects, and topographers, it became clear that a solution for Africa needed to be fundamentally different—built to withstand the continent’s uniquely harsh and dynamic construction environments.

This led to the creation of COROSOLS, a startup with the ambition to develop robust, tailored robotic solutions, beginning with the automation of construction layout. The initial project was championed by the UM6P Explorer program, which provided critical early-stage mentoring and the funding necessary to begin. As the technical challenges intensified, the project evolved significantly with the addition of Youssef Makhlouf as CTO. Becoming a core, full-time partner alongside Hamza, his hands-on engineering and relentless drive have been the force behind building the physical prototype. The team was further strengthened by Amine Ait Oufkir and Ayyoub El Kasmi, who provide specialized, part-time consulting expertise in BIM, architecture, and AI.

Hardware First, Precision Always

Bringing a deep-tech solution like COROSOLS to life follows a fundamentally different path than a software startup. While a digital product can often be launched with just a laptop and a developer, building a physical, intelligent robot requires tangible hardware, significant upfront investment, and a robust support system long before a prototype is even functional. This journey from a market-validated idea to a field-ready MVP was a multi-stage process, made possible only through the powerful support ecosystem at UM6P. The first operational step was securing initial funding to purchase the essential hardware components.

This is where the UM6P Explorer program played an invaluable role, providing the seed budget that allowed us to place our first orders. This phase tested our resilience, demanding patience as we navigated long hardware delivery times while keeping the project’s momentum alive.

Once the initial components were in hand and a basic prototype began to take shape, the project needed to accelerate. This led to the next critical phase with The Bench, UM6P’s scientific incubator. This program was a game-changer, providing the resources—including a dedicated budget and a salary for its founder—that enabled him to commit full-time to leading COROSOLS for an entire year. This level of dedicated focus is a rare luxury for early-stage deep-tech startups and was essential for tackling the complex engineering challenges and rapidly advancing the robot’s development.

With a dedicated team and a functional prototype, the final deployment challenge was achieving the professional-grade precision demanded by the construction industry. This was addressed by establishing a strategic R&D partnership with Leica Geosystems, a global leader in measurement technology.

This collaboration provided access to their industry-leading robotic total stations, allowing the team to integrate this crucial technology and elevate the robot’s accuracy to the millimeter level required for commercial use.

This journey demonstrates that for a deep-tech project to progress from concept to reality, it requires an ecosystem of support—from university incubators to formal industry partners—to accompany it from the very beginning.

Precision in Motion: What COROSOLS Delivers

The primary result of this dedicated development effort is a tangible, fully functional prototype of the COROSOLS layout robot. This is not just a concept; it is a working machine that successfully validates the core solution. The prototype’s key achievements include

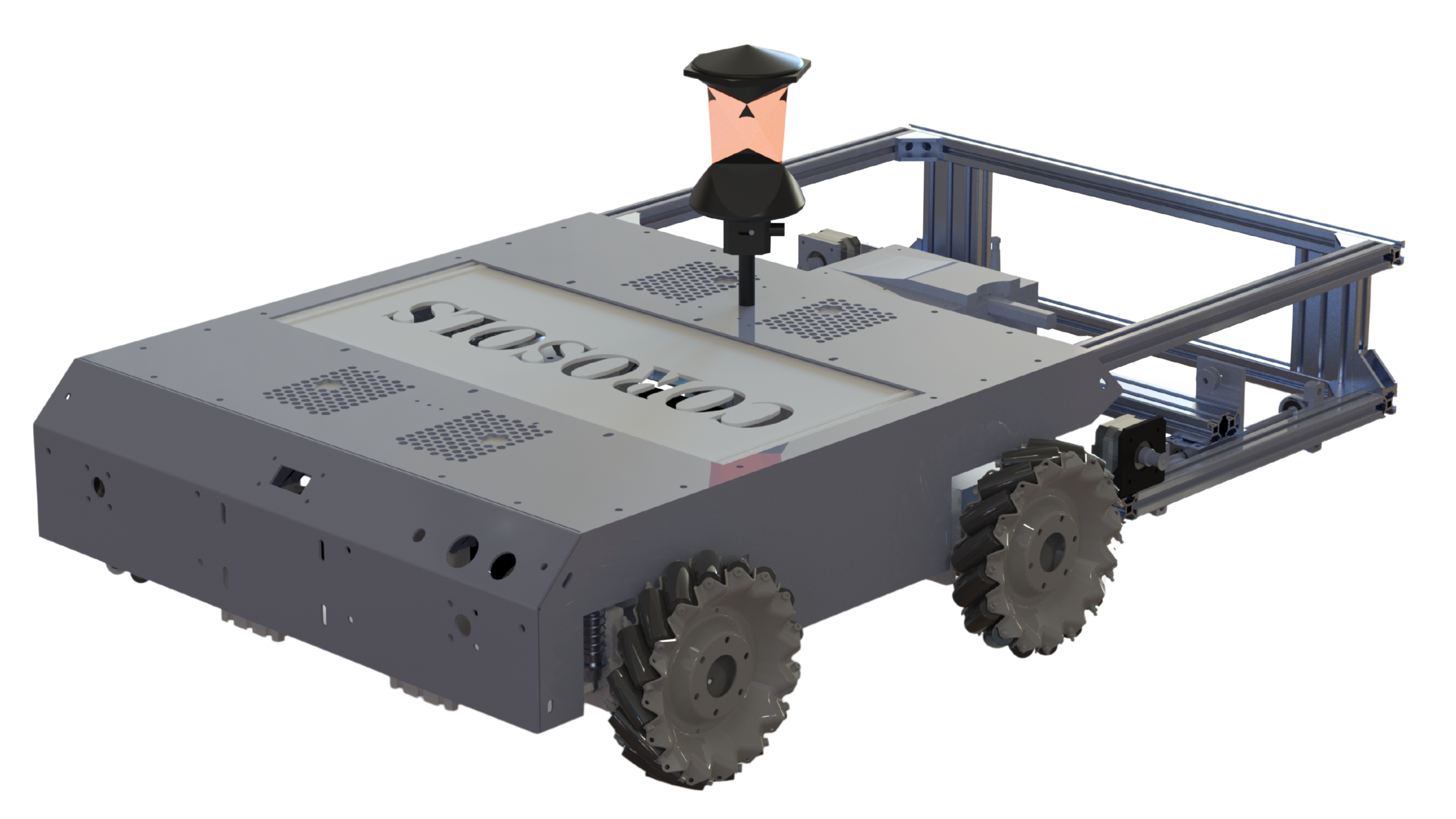

A Robust Mechanical Platform: A resilient system featuring independent suspension and omnidirectional Mecanum wheels, specifically engineered to operate effectively on the rugged and uneven terrain typical of African construction sites.

A Proprietary Printing Algorithm: The core software is fully operational, capable of seamlessly translating complex BIM and AutoCAD files into precise instructions for the robot to execute on the ground.

A Custom-Designed Spray-Paint System: A reliable printing method using spray paint, which is ideal for the dusty surfaces found in construction, offering a safer and more practical alternative to inkjets that clog or hazardous lasers.

Integration with High-Precision Positioning: Through the R&D partnership with Leica Geosystems, the robot successfully integrates with a robotic total station, a crucial achievement for ensuring professional-grade accuracy.

In its current state, the robot consistently achieves a printing precision of 5mm, with ongoing refinements aiming to reach an even higher standard of 2mm.

This progress has already generated significant industry interest. As a result, on-site demonstrations are now being scheduled with major Moroccan construction companies in the coming weeks, moving the project from a controlled test environment into real-world validation.

Impacting Construction from All Angles

The impact of COROSOLS is transformative across economic, environmental, and social dimensions. By automating a process that is currently a major bottleneck, the robot delivers clear and measurable benefits:

Economic Impact: The solution is up to 10 times faster and 10 times more precise than manual methods. By reducing rework by over 50% and boosting overall productivity by 300%, it directly translates into massive cost savings for construction companies, faster project completion, and enhanced profitability.

Environmental Impact: Construction rework generates significant waste. By ensuring layouts are right the first time, the robot minimizes the waste of high-polluting materials like cement and reduces the energy consumed in demolition and reconstruction, contributing to a more sustainable construction industry.

Social Impact: The robot dramatically improves worker safety, especially in high-rise buildings where layout tracing can be hazardous. It also alleviates the physical strain and stress associated with manual layout, allowing skilled workers to focus on higher-value construction tasks.

The primary beneficiaries are large-scale construction firms, but the technology also offers immense value to architects, engineers, and industrial companies needing precise layouts. Ultimately, COROSOLS opens the door to a new standard of quality and efficiency in African infrastructure development.

Beyond the First Line: What’s Next

COROSOLS is more than just a robot—it’s a powerful answer to a multi-billion-dollar problem in the construction industry. By automating layout tracing with a robot built for the African context, the startup brings digital precision directly to the field.

As a product of the UM6P innovation ecosystem, COROSOLS embodies the spirit of African tech innovation: local, bold, and future-driven. This robot is the first step in building a new generation of tools that will shape Africa’s infrastructure—one precise line at a time.

Leave a Reply