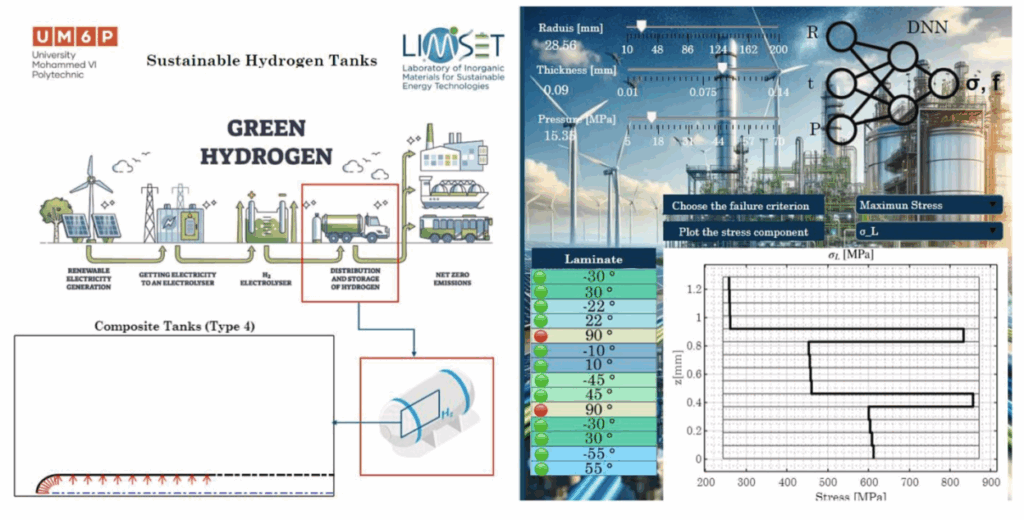

UM6P develops an integrated deep learning and optimization framework to predict damage and optimize composite high-pressure hydrogen tanks for green energy transition.

UM6P Impact | Science in Action #12

Why Hydrogen Needs Better Storage

Hydrogen is widely recognized as a key pillar in the global transition toward clean and sustainable energy systems. As a zero-carbon energy carrier, it has the potential to decarbonize sectors ranging from transportation to industry. However, one of the central challenges hindering its widespread adoption is the safe, efficient, and cost-effective storage of hydrogen at high pressure.

Composite overwrapped pressure vessels (COPVs) have emerged as the preferred solution for high-pressure hydrogen storage. Their lightweight, high-strength design offers exceptional performance compared to metallic tanks. Yet, these structures face significant challenges related to mechanical stresses, failure mechanisms such as delamination or fiber breakage, and degradation over time under cyclic loading.

Accurately predicting these failure modes and optimizing design parameters are essential to ensure safety and reduce costs. This project was conceived in direct response to these scientific, technological, and societal challenges. It addresses the critical need for advanced tools capable of predicting damage in composite hydrogen storage tanks while enabling optimized design tailored to safety and performance requirements.

At the University Mohammed VI Polytechnic, this research aligns with the institution’s broader mission to drive innovative, sustainable solutions for energy systems. It reflects UM6P’s commitment to supporting Morocco’s and Africa’s green transition, developing advanced engineering solutions for hydrogen technologies.

From a Field Problem to a Research Idea

The idea for this project arose from a clear observation in the field: while composite tanks are essential for safe hydrogen storage, current design processes often rely on simplified models and costly physical testing. Engineers lack predictive tools that can account for the complex, anisotropic behavior of composite materials under realistic loading and environmental conditions. The need was further reinforced by industry feedback highlighting the difficulties in predicting failure mechanisms and optimizing tank designs while balancing weight, strength, and cost.

Led by Professor Mourad Nachtane at UM6P’s Laboratory of Inorganic Materials for Sustainable Energy Technologies (LIMSET), the project gathered expertise in composite materials, structural analysis, and artificial intelligence.

Partners included Arts et Métiers Institute of Technology (France), ENSTA Bretagne, and industrial partner S Vertical Company, ensuring a multidisciplinary and applied approach.

The initial goal was clear: develop an integrated, AI-powered framework capable of accurately predicting stress and failure in composite hydrogen tanks while identifying optimal design parameters to prevent failure and ensure safe, cost-effective deployment.

From Theory to AI Integration

The project unfolded through a series of well-defined, rigorous stages:

Analytical Modeling: Using 3D elasticity anisotropy theory, the team developed a robust analytical framework to model stress and strain distributions in filament-wound composite tanks, capturing the anisotropic behavior of carbon fiber/epoxy laminates.

Validation with Literature and FEA: The analytical model was validated against existing studies and advanced finite element analysis (FEA) using Abaqus and WoundSim software. These simulations accounted for real-world geometries, layups, and loading conditions.

Data Generation: A large dataset of stress distributions was generated by systematically varying design parameters (pressure, layer thickness, tank radius) using the validated models.

Development of Deep Neural Networks (DNNs): Leveraging this dataset, the team trained DNNs to predict stress components (longitudinal, transverse, in-plane shear, through-thickness) for multi-layered composite laminates. The models were carefully designed with multiple hidden layers and trained using advanced optimization algorithms to ensure high accuracy.

Integration of Differential Evolution Algorithm (DE): To move beyond prediction and achieve true design optimization, a DE algorithm was integrated. This evolutionary approach iteratively searched for optimal design configurations that minimize failure risk while satisfying operational constraints.

Creation of a Graphical User Interface (GUI): Recognizing the need for accessible tools for engineers, the project developed a user-friendly GUI. This interface allows users to input key parameters, instantly visualize stress distributions and failure criteria, and explore optimized designs.

What the Project Delivered

This project delivers clear and meaningful impacts at multiple levels:

Technical Impact: By enabling precise prediction of stress and failure in composite hydrogen tanks, the framework helps engineers design safer, lighter, and more cost-effective storage solutions. This directly addresses one of the key barriers to scaling hydrogen infrastructure.

Industrial Relevance: The integration of AI-powered prediction and optimization reduces reliance on expensive physical prototyping and testing, accelerating design cycles and cutting costs for manufacturers.

Academic and Research Impact: The project advances the state-of-the-art in combining analytical mechanics, FEA, and deep learning for composite structures. It provides a validated methodological framework that can be extended to other advanced materials or applications.

Environmental and Societal Impact: By improving the reliability and affordability of hydrogen storage, this research contributes to the broader adoption of hydrogen as a clean energy carrier. This supports national and international goals for decarbonization and energy transition.

Beneficiaries: Engineers and designers in the hydrogen sector, composite materials manufacturers, policy-makers working on hydrogen infrastructure planning, and ultimately, communities seeking cleaner energy solutions.

Perspectives: The framework is adaptable and can be expanded to include additional design variables, material systems, or operating conditions. Future work could integrate real-world monitoring data for predictive maintenance, further enhancing safety and reliability.

A Foundation for Hydrogen Innovation

This project exemplifies the power of combining advanced simulation techniques, artificial intelligence, and user-friendly tools to solve critical energy challenges. By delivering a validated, AI-enhanced framework for predicting and optimizing the design of composite hydrogen storage tanks, the team has paved the way for safer, more efficient, and cost-effective hydrogen infrastructure.

The work stands as a strong contribution to sustainable energy transitions, supporting the broader deployment of clean hydrogen solutions. Looking ahead, the approach offers a robust foundation for future innovations in composite design, predictive maintenance, and AI-driven engineering.

Connect with Prof. Nachtane’s Vision: Shaping a Smarter Hydrogen Storage System

Behind every powerful scientific breakthrough lies a deep conviction. For Professor Mourad Nachtane, that conviction is clear: bridging the gap between complex engineering theory and real-world application is not a luxury—it’s a necessity. As the lead investigator of this project at UM6P’s Laboratory of Inorganic Materials for Sustainable Energy Technologies (LIMSET), Prof. Nachtane brought together a unique blend of expertise in composite materials, structural mechanics, and AI-powered engineering tools, driven by the desire to support Africa’s energy transformation.

His leadership extends far beyond campus. As Head of the Hydrogen Storage Team within the Green Hydrogen Division of the International Association for Hydrogen Energy (IAHE), he is at the forefront of global collaboration in the field. His work has earned him major recognitions, including the IAAM Scientist Award 2025, the Peer Prize for Climate, and distinctions from the French Navy and the Francophonie Innovation Network.

Through this project, Prof. Nachtane and his team have turned cutting-edge AI and validated modeling techniques into a practical, accessible tool—one that can be used by engineers across industries to make hydrogen storage safer, lighter, and smarter. His vision isn’t just technical. It’s transformative.

By integrating deep learning and optimization into a user-friendly interface, we believe we’ve taken a meaningful step toward safer and more sustainable hydrogen energy systems.

Want to Dive Deeper?

The research featured in this article is grounded in a peer-reviewed scientific publication. To explore the full methodology, datasets, and technical framework behind the AI-powered design tool, read the original article on ScienceDirect

This study offers valuable insights for engineers, researchers, and innovators committed to building the next generation of sustainable energy systems.

Leave a Reply