Pr. Jihane Moumouh is Harnessing Machine Learning for Smarter, Greener, and More Resilient Industries.

UM6P Impact | Change Makers #01

In this Change Makers interview, we explore with Pr. Jihane Moumouh how data-driven modeling is reshaping phosphoric acid production, one of the most critical processes in fertilizer manufacturing. By moving beyond traditional laboratory analyses, researchers are demonstrating how machine learning can predict, optimize, and transform industrial performance in real time. From the industrial site of Jorf Lasfar to broader applications in energy, water, and sustainability, this work reveals how AI and machine learning are becoming catalysts of Industry 5.0 — a future where efficiency meets resilience and sustainability.

When Data Becomes the New Catalyst of Chemistry

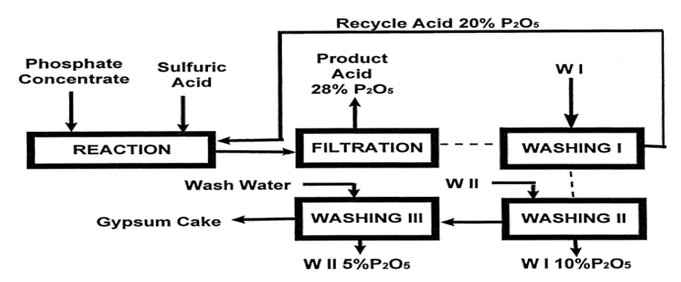

Data-driven modeling represents a turning point for phosphoric acid production because it overcomes the limitations of traditional methods, which are slow, costly, and heavily dependent on laboratory analyses. By exploiting industrial data, particularly from the attack-filtration section, machine learning models can rapidly and accurately predict key outputs such as acid quality, gypsum purity, reaction temperature, and overall yield. This enables operators to minimize P2O5 losses, improve process efficiency, and achieve higher product purity in real time. Compared to classical methods, data-driven approaches enable the analysis of complex interactions and non-linear effects, transforming process monitoring from reactive to predictive. This leads to faster optimization, lower costs, greater adaptability, and improved efficiency, competitiveness, and sustainability in phosphoric acid production.

Bringing Algorithms to the Factory Floor

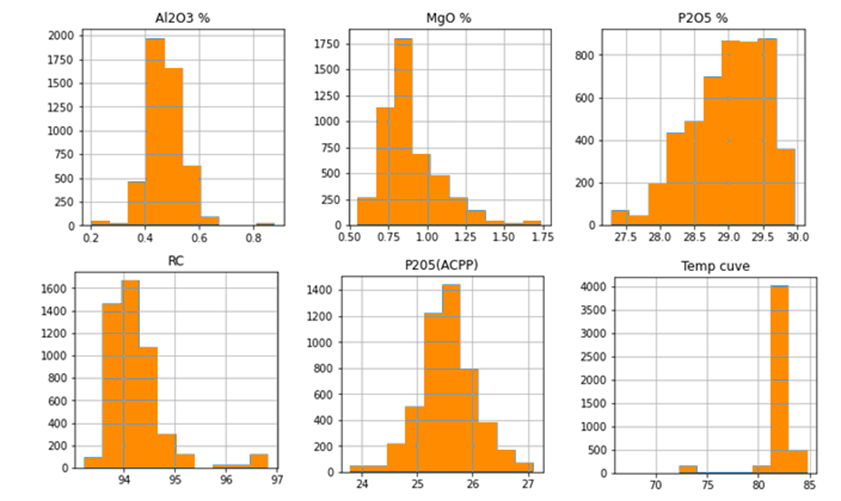

At the Jorf Lasfar industrial site, more than 5000 operational data points were collected and analyzed. As illustrated in Figure 2, the distributions of these input variables form the basis for training both the multi-linear regression (MLR) and the multi-target regression tree (MRT) models. By combining sensor measurements with machine learning, operators can now predict deviations before they affect production performance. This shift from traditional laboratory-based analysis to real-time, data-driven operations enhances process stability, reduces material losses, and improves both yield and energy efficiency.

Cracking the Code of Complexity with Decision Trees

Decision tree regression (MRTs) outperformed multi-linear regression (MLR) because it could capture the non-linear and interaction-heavy relationships of the attack-filtration process, as evidenced by its much higher R² (0.994 vs. 0.3308). This indicates that the system is inherently complex and cannot be adequately represented by a simple linear model. Decision trees not only outperformed linear models but also provided interpretable rules that reveal how input parameters drive yield and quality.

The Secret Ingredients Behind Higher Yields

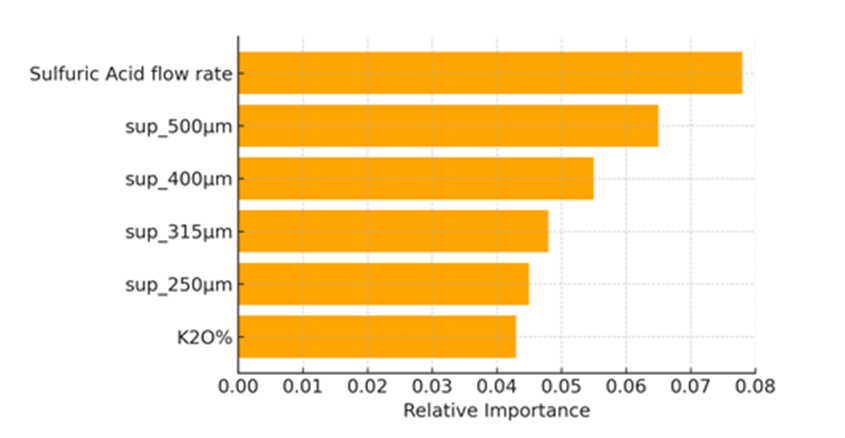

As revealed in Figure 3, one of the strongest levers in phosphoric acid production is the Sulfuric acid flow rate, which sets the pace of the chemical reactions and directly influences how efficiently the phosphate rock dissolves. The analysis also shows the crucial role of particle size distribution: larger particles slow the process, while finer ones react more quickly. By focusing on these dominant factors, operators can fine-tune acid dosing and particle size control, leading to steadier operations, smoother reactions, and higher overall efficiency across the plant.

From Efficiency to Sustainability: A Greener Industry in the Making

Machine learning is emerging as a key enabler of greener industry. In phosphoric acid production, it reduces losses of valuable P2O5, improves washing steps, and minimizes gypsum waste. Beyond efficiency gains, these advances contribute to more sustainable supply chains, securing fertilizer production that meets growing global food demand while lowering the environmental footprint.

This transformation is part of the broader journey from Industry 4.0 to Industry 5.0. Whereas Industry 4.0 centered on automation and efficiency, Industry 5.0 shifts the focus to human-centric, resilient, and sustainable production systems. By augmenting human expertise with transparent, data-driven insights, machine learning not only enhances industrial performance but also drives the vision of smart, green, and adaptive ecosystems for the future.

Beyond Acids: Where Else Can Data Science Change the Game?

Pr. Jihane Moumouh’s take : Currently, I have applied this data-driven methodology to reverse osmosis desalination and wastewater treatment processes. I see many opportunities to extend it to other areas of the chemical and energy industries, such as fertilizer production, green hydrogen production to optimize production conditions and reduce emissions, renewable energy systems for predictive maintenance and efficiency improvement, and energy storage and battery technologies to predict degradation and optimize performance.

It may also prove useful in the field of carbon capture and utilization (CCU), where complex data sets can be leveraged to improve separation efficiency and accelerate scaling. Beyond process optimization, I see this methodology as an essential catalyst in engineering for exploring data for decision-making and innovation, supporting the transition to Industry 5.0, where AI complements human expertise to achieve sustainable, resilient, and human-centered industrial systems.

Fast Forward to 2035: Smarter, Human-Centric Industries

In the next ten years, AI and machine learning will transform industrial decision-making from reactive to predictive and prescriptive, enabling real-time optimization, improved sustainability, and resilient supply chains. Within the Industry 5.0 framework, they will augment human expertise with explainable insights, creating intelligent, adaptive, and human-centric operations.

Seeing Data Differently: A Researcher’s Personal Awakening

Pr. Jihane Moumouh’s answer : This project transformed the way I perceive the link between data science, industry, and sustainability. I now view data as a strategic resource that, when properly explored, reveals the underlying dynamics of industrial processes and enhances the understanding of their physical models. Beyond analysis, it emerges as a powerful tool for informed decision-making, showing how data science can drive industries toward higher efficiency, stronger sustainability, and continuous innovation.

How Young Researchers Can Bridge the Gap

Pr. Jihane Moumouh’s advice : My advice to young researchers is to treat data science not just as a technical discipline, but as a bridge to real-world impact.

Young researchers should ensure the collection of quality and sufficient industrial data, develop a solid understanding of processes, and be able to interpret modeling results in an industrial context. By linking advanced data science with real challenges and sustainability goals, they can turn data into actionable knowledge for smarter and more resilient industries.

Looking Ahead: Data as a Driver of Sustainability

This interview highlights how machine learning is more than a technical tool — it is a driver of industrial transformation. From minimizing waste and stabilizing quality to building sustainable supply chains, the integration of AI into industrial operations is paving the way toward smarter, greener, and human-centered ecosystems.

As the researcher reflects, the message to the next generation is clear: data science is not just about algorithms — it is about creating real-world impact by bridging industry, sustainability, and innovation.

I now view data as a strategic resource that, when properly explored, reveals the underlying dynamics of industrial processes and enhances the understanding of their physical models. — Pr. Jihane Moumouh

Want to Dive Deeper ?

Learn more about Pr. Jihane Moumouh’s publication here.

Leave a Reply